The Wide Range Humbucker and The Genius of Seth Lover

/The Wide Range Humbucker was introduced in 1971 and originally discontinued in 1979. The Wide Range pickup was unique because of its threaded CuNiFe pole piece magnets, but as we’ll see, they aren’t the only key to the unusual design of this pickup.

The Wide Range pickup was invented for Fender by Seth Lover, who also invented Gibson’s PAF humbucker. Lover left Gibson for “a better offer” at Fender in 1967. While Fender’s marketing department initially wanted him to make a more or less exact copy of the PAF (the patent was about to expire), Lover had other ideas. He wanted to make a humbucker with a response more like the single coil pickups for which Fender was known. Part of how he did this was to incorporate CuNiFe magnets as pole pieces in the Wide Range pickup. Lover knew that CuNiFe pole pieces had properties that would enable this response,

“They don't increase the inductance of the coil”…”so higher frequencies were more pronounced.”

While the choice of CuNiFe is an obvious deviation from conventional pickup materials, there are other design differences that distinguish the Wide Range Humbucker from conventional Strat-style single coils and PAF-style humbuckers. Figure 1 shows examples of the different types. The Strat-style single coil is simply a coil wound around 6 magnetic AlNiCo (most typically AlNiCo 5) pole pieces. The magnets are oriented under the strings and charge them directly. The PAF humbucker consists of two coils, side by side. The coils are configured with their magnetic and current flow directions such that external noise picked up by the coils cancels, while the signal picked up by the vibrating string in the respective coils is additive. In this way they “buck the hum”, but leave the string signal intact. The magnetic charge comes from an AlNiCo magnet that is situated transversely underneath the coils and between the two rows of pole pieces, such that one coil is oriented to magnetic North, and the other to magnetic South. The pole pieces in a PAF are made out of highly magnetically permeable low carbon steel. They do an effective job of directing the magnetic field of the pickup magnet to the string, so it can be magnetized. They also do a very good job of concentrating the flux generated by the vibrating string in the core of the coil, significantly increasing the inductance and hence the output of the pickup. The Wide Range Humbucker consists of two side by side coils configured for humbucking like the PAF. Instead of placing the magnet below the coils and in a transverse orientation like he did in the PAF however, here Lover utilized CuNiFe magnets as the pole pieces, charging the strings directly in a way more similar to the Strat-style single coil. The coils are wider than the PAF coils, encompassing a larger area. Lover knew that this configuration would be critical to increase output, especially when using the lower permeability CuNiFe pole piece.

So that’s the recipe for the Wide Range Humbucker: a CuNiFe pole piece and a bigger coil to boost the output. At least that’s what I understood going in, and what you’ll hear almost everybody else say, but there’s something else going on. Notice the thin steel plate under the coils in the Wide Range Humbucker in Figure 1. This plate is not insignificant. In fact it is arguably the most important part of the Wide Range design, and I’ll show you why.

But first, let’s talk about the genius of Seth Lover. He understood exactly how pickups worked, as he told Seymour Duncan:

So, obviously Lover was looking at pickup design from the perspective of the string being the center of flux. Given his obvious and documented knowledge and curiosity he must have also been thinking about how this flux was interacting with the construction materials of the pickup. He knew that the function of the magnet was to magnetize the string, and he realized the implications of using a low permeability material like CuNiFe (not as a magnet but as a pole piece) and he designed for it by making the coils bigger.

He must have also understood the implications of the steel plate, especially considering that he used steel in the Gibson PAF humbucker construction some 20 years earlier. He understood steel’s properties and its role as a flux path. And those implications are significant.

I deconstructed a new reissue Fender Wide Range Humbucker with CuNiFe magnets. The component parts are shown in Figure 2. I stripped the pickup down to just the bobbins, coils and baseplate, all magnetically insignificant parts, although I suspect that the baseplate may have a significant effect on Q. The pickup was analyzed for impedance response as a function of frequency, and the inductance was measured at 20 Hz (the lowest available measurement frequency). The pickup was reconstructed, one piece at a time, and measured at each stage. The results are shown in Figure 3. As the data show, the single biggest influence on the pickup inductance (other than the coils themselves) is the steel plate, increasing the inductance of the assembly by almost 25%. The CuNiFe poles, in comparison, only contribute an 8% increase. The effect of the cover on inductance is negligible. The Q of the pickup is relatively unaffected by the presence of the steel plate, probably because it is not in the core of the coil. The most significant effect on Q comes, a bit surprisingly, from the cover. In most cases the effect of the cover (for instance, in a PAF-style humbucker) is measureable, but not nearly this significant. Perhaps this is because the material in the core of the core is of such low permeability that the cover has more of a relative effect. In any case, it could be argued that the steel plate is the single most important magnetic component of the pickup.

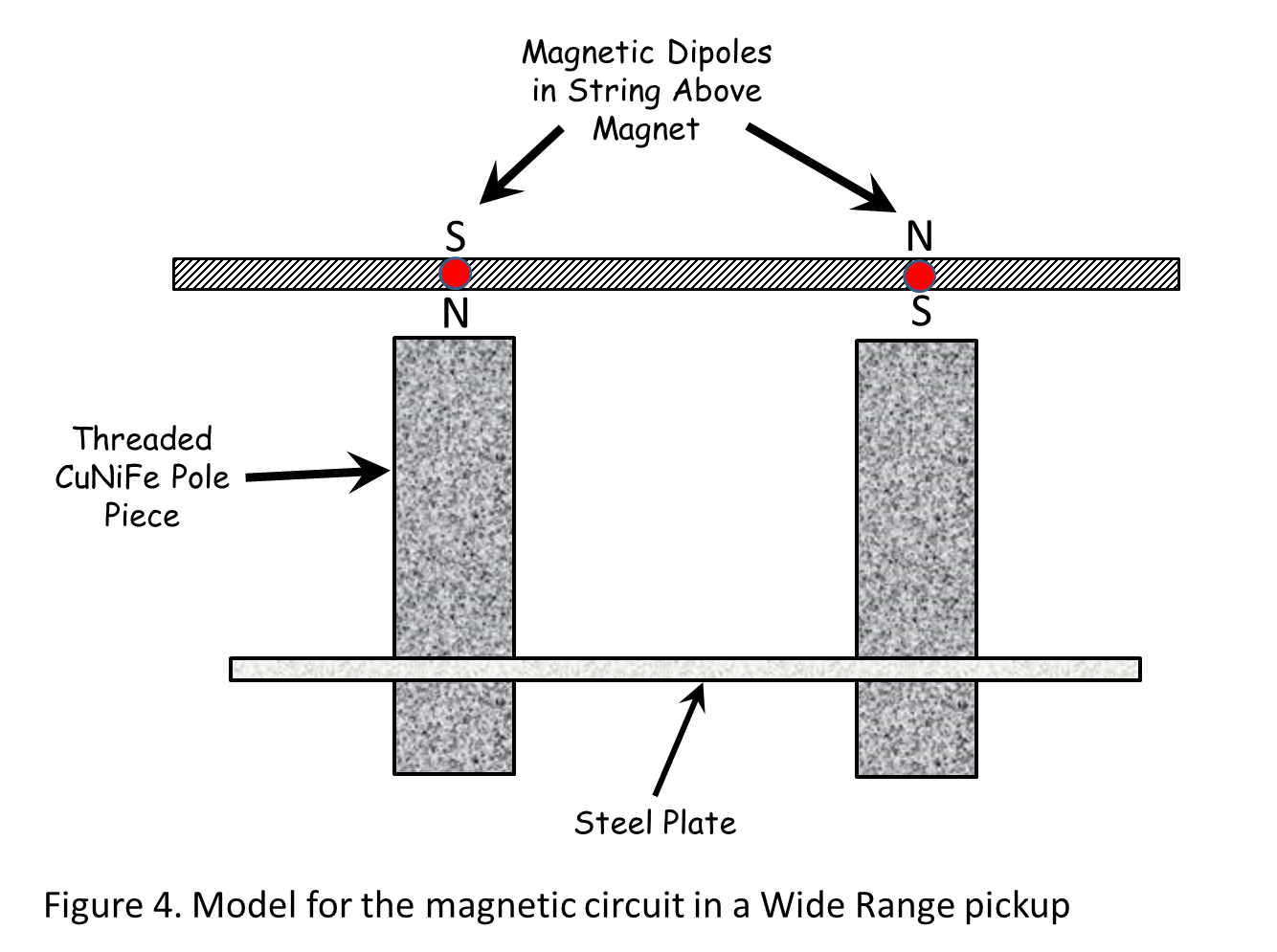

To understand why this would be, we can simulate the flux in the magnetic geometry of the pickup. Figure 4 shows a cross section of the pickup, and the geometry that is used as the magnetic model. Figure 5 highlights the part of the model to be focused on; in fact it’s the only part that matters in terms of signal generation, the part that goes through the volume encompassed by the coil. Only magnetic flux that passes within the envelope of a winding will generate a signal in the coil. Figure 6 gives the results of simulations corresponding to the pickup reconstruction sequence and data shown in Figure 3. With only the coils and base plate, the flux field from the string is unaffected, and is symmetric about the string. With the steel plate introduced, the flux field is pulled down towards the plate, expanding the field and generating a more uniform and stronger field in the volume encompassed by the coil, directly above the plate. The addition of the CuNiFe pole pieces results in only a slight concentration of flux in the poles, the general shape and density of the flux field in the volume of the coil is relatively unaffected. The cover is not modeled as it has no magnetic effect, at least none that can be modeled easily. The effects of materials on Q are complicated, but we will deal with them in a future blog post.

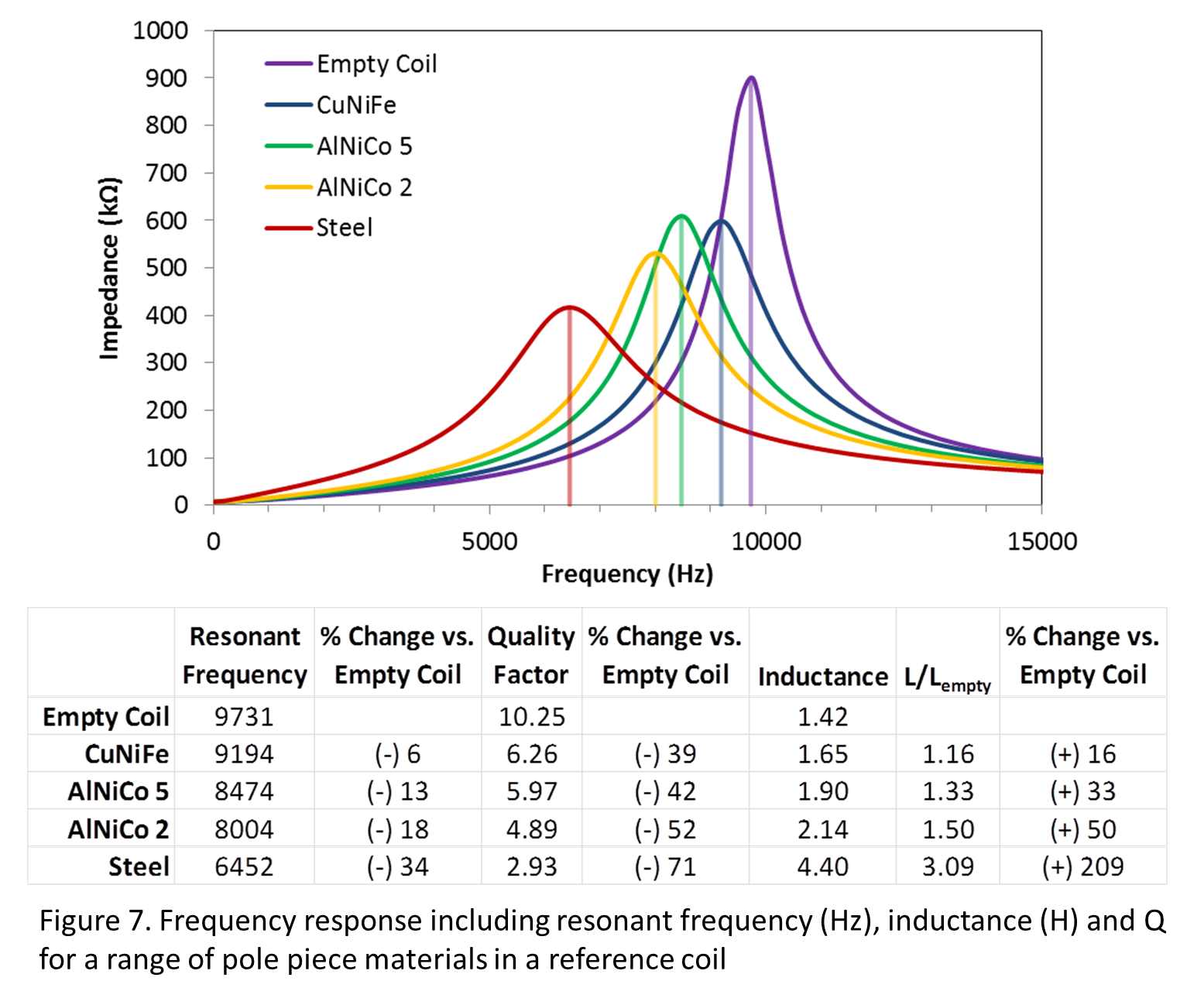

By measurement and by simulation, CuNiFe has only a moderate effect on the frequency response and inductance of this pickup, but how does it compare to other materials? You’ll notice that 6 of the pole pieces are missing in Figure 2. Well, they were installed in a test Strat coil at the time. This is a reference coil (basically an empty coil from an import ceramic pickup assembly) that we use to compare pole piece materials. Figure 7 shows the impedance response as a function of frequency and the inductance for CuNiFe compared to AlNiCo 5, AlNiCo 2 and the stock steel pole pieces that were originally installed in the pickup. The empty coil is also shown for reference. CuNiFe imparts only about a 20% inductance increase and a very small change in resonant frequency. In fact, CuNiFe is less permeable (imparts a lower inductance increase) even than AlNiCo 5. As such, CuNiFe on its own would be 1) a very “weak” pole piece and 2) even more “transparent” than AlNiCo 5. Note that CuNiFe also exhibits the highest Q value of any of the materials.

Figure 8 illustrates simulations of the effect of the permeability of the pole piece in the magnetic geometry of the Wide Range Humbucker. Note that the relative permeability of CuNiFe was set to 1.5 in the simulations illustrated in Figure 6. The relative permeability of AlNiCo 5 is around 2 and AlNiCo 2 is assumed to be 7. Steel is set here to 1000. As the figure illustrates, even small increases in permeability result in the flux field collapsing into the pole piece, disrupting the wider and more consistent flux field that is obtained with the lower permeability pole. So, we can see that even as the steel plate enables the wider field, CuNiFe, due to its almost total magnetic “transparency” in the flux field of the string, enables it to be maintained while also providing for the string to get magnetized. The combination of these material properties and their utilization in this efficient and innovative piece of engineering results in a pickup with a very unique magnetic structure, really one of a kind in pickup design.

And I have to believe that Seth Lover understood all of this. In fact, I have come to the conclusion that the “Wide Range” in the pickup name most specifically refers to the wider range of the flux field enabled by the large coils and especially the steel plate that spreads the field out to fill those coils. Not forgetting the CuNiFe which does not concentrate the field much at all, enabling it to remain spread out. He did this all very purposefully with the goal of a pickup that would match humbucker output and noise rejection performance with more of a Fender type of response. What he got met those goals, but it is really neither a PAF humbucker nor a Fender single coil, it’s a truly unique design that stands on its own.

But, as mentioned in the intro, the Wide Range was discontinued in 1979 or so. Not particularly popular in its initial release, the design sat in the backwater of pickup history for many years. But like so many other things, people eventually started to develop an appreciation and a nostalgia for the design and demand for reproduction pickups grew. Early reproductions were less than authentic, mostly due to the unavailability of CuNiFe, and generally amounted to a PAF-style humbucker under a Wide Range cover. Eventually however, interest rose to the point that sources of CuNiFe were identified, and new manufacturing of CuNiFe was initiated, at least on a limited basis. Other permanently magnetic materials have been substituted for CuNiFe in otherwise faithful designs, most typically AlNiCo alloys or another magnet type that can be threaded (although even threaded AlNiCo has now become available) called FeCrCo. Figure 9 illustrates the frequency and inductive response of a range of Wide Range Humbucker reproduction pole piece materials measured in the reference strat coil. While they are all clustered in a range, CuNiFe exhibits the lowest permeability (as measured by the relative increase in inductance versus the reference coil) and the highest resonant frequency. FeCrCo alloys 5 and 2 are clustered adjacent to their respective AlNiCo “cousins”. FeCrCo exhibits the highest Q out of any of these alloys. These pole piece alloys would be expected to exhibit the behaviors simulated in Figures 6 and 8 based on permeability in the range of just over 1 to about 10. Any of these alloys will cause more of the magnetic flux to collapse into the core, compared to CuNiFe, so with any substitute some of the truly unique behavior that Seth Lover designed into this pickup will be lost. That being said, the differences in these alloys isn’t huge, and armed with this information the educated consumer (or even pickup designer) could tailor the design to different tastes. For instance, if you want to fatten it up a bit, go with the high permeability FeCrCo 2. Or perhaps use the high Q FeCrCo 5 to account for the typically higher resistance pot values (1 MΩ) that were originally mated with the Wide Range Humbucker. Another interesting thing about CuNiFe is that its electrical conductivity is about 3 times higher than any of the other alloys. This property means that it has a more significant eddy current effect than we might otherwise expect. But, that’s also a topic for a future blog.

What strikes me about the genius of Seth Lover is how much he was able to understand and accomplish with so much more limited technological resources than we have now. It was just so much harder and more expensive to do anything back then, for one thing. Today, I can go take a full detailed and accurate measurement of a pickup in minutes (probably seconds if I wanted to spend a few thousand dollars and update my LCR meter), port the data (invirtual form, never having to transcribe anything) to my computer where I can import it into a spreadsheet and manipulate it in any number of different ways in seconds. In Lover’s day it would’ve taken a good part of a day just to take the measurements and make up a hand-drawn and plotted chart: oh and if you mess up the chart, get out the White-Out or do it all over again. In any event, in this or any other technological endeavor, it’s always good to remember that we stand on the shoulders of giants.